News

-

Rubber expansion joint- A Flexible Tool for Pipeline Connection

In industrial pipeline systems, rubber expansion joints are a crucial component that not only connect the pipeline, but also absorb vibration, compensate for temperature changes, and play a critical role in the normal operation of the pipeline system. This article will introduce the size, classif...Read more -

Socket welding flange vs other flanges: selecting the correct pipeline connection method

In the industrial field, pipeline connections are crucial, and selecting the appropriate flange type is crucial for the performance and safety of pipeline systems. Among numerous flange types, Weld Neck flange is one of the common and important types. However, compared to other flange types, it h...Read more -

Differences between DIN2503 and DIN2501 About Plate Flange

DIN 2503 and DIN 2501 are two different standards designed by the German Organization for Standardization (DIN) for flat welding flanges. These standards define the specifications, dimensions, materials, and manufacturing requirements for flange connections. Here are some of the main differences ...Read more -

GERMANY Exhibition-International Tube and Pipe Trade Fair

Dear partner, the 2024 Pipe and Wire Exhibition in Dusseldorf, Germany is about to begin. Our company will also participate in this exhibition. We will now inform all friends of our participation time and exhibition location.Read more -

Understanding the difference Between stainless steel steel and carbon steel in industrial Applications

In the Fields of industrial fabrication and construction, as well as in the flange adjustment sell by our company, stainless steel steel and carbon steel are two park metallic element material with different feature and applicability. understanding their similarity and difference aid to better ch...Read more -

API 605 Flanges: Critical Connection Components in the Oil and Gas Industry

API 605 standard flange is one of the flange connection standards developed by API, mainly used for the connection between pipelines, equipment, and valves. This standard specifies the size, shape, material, and connection method of flanges, aiming to ensure safe and reliable connections between ...Read more -

BS4504-Plate Flange

BS4504 is a part of the British Standard that specifies the standard specifications for flanges used in pipeline connections. The BS4504 standard includes various types of flanges, including Plate flanges. The following is general information about the BS4504 Plate flange. Specific dimensions, pr...Read more -

Comparison of dyer’s rocket neck flange and home plate flange

When discourse dyer’s rocket neck flange and home plate flange, we can see that they rich person some similarity and difference in structure, application, and performance. Similarities 1. flange connection: Both are flange use to connect pipe, equipment, and valve, form a tight grapevine sy...Read more -

Compare aluminum flanges with stainless steel flanges and carbon steel flanges.

Aluminum flange Material characteristics: Lightweight: Aluminum flanges are made of aluminum alloy, making them lightweight and suitable for applications that are sensitive to weight requirements. Thermal conductivity: Good thermal conductivity, commonly used in applications that require heat di...Read more -

Aluminum Flanges

Flange is a flat circular or square connecting component with holes on its edges for connecting flanges together through bolts or nuts. Aluminum flanges are usually made of aluminum alloy and are mainly used in pipeline systems to provide connection points between different components, thereby co...Read more -

The differences between aluminum flanges and carbon steel flanges

Aluminum flange and carbon steel flange are two different materials of flanges, which have some differences in performance, application, and some physical and chemical properties. The following are the main differences between aluminum flanges and carbon steel flanges: 1. Material: Aluminum flang...Read more -

Large size rubber expansion joints: flexible guarantee for pipeline systems

Rubber expansion joints are important auxiliary equipment in pipeline systems, playing a crucial role in handling issues such as thermal expansion, contraction, vibration, and displacement of pipelines. This article will focus on the characteristics, application fields, and importance in industry...Read more -

Standard About One-piece Insulating Joint/One-piece Insulation Joint

Integrated insulation joints are a critical pipeline connection device designed to provide excellent insulation performance to meet electrical or thermal conductivity requirements. These joints are widely used in various industrial fields and have made important contributions to the reliability a...Read more -

Standard About Insulated Flange

Insulated flange is a device used to connect two flanges in a pipeline system. Its main feature is to add an insulation layer between the flanges to prevent heat, current, or other forms of energy from conducting at the flange connection point. This design helps to reduce energy loss, improve sys...Read more -

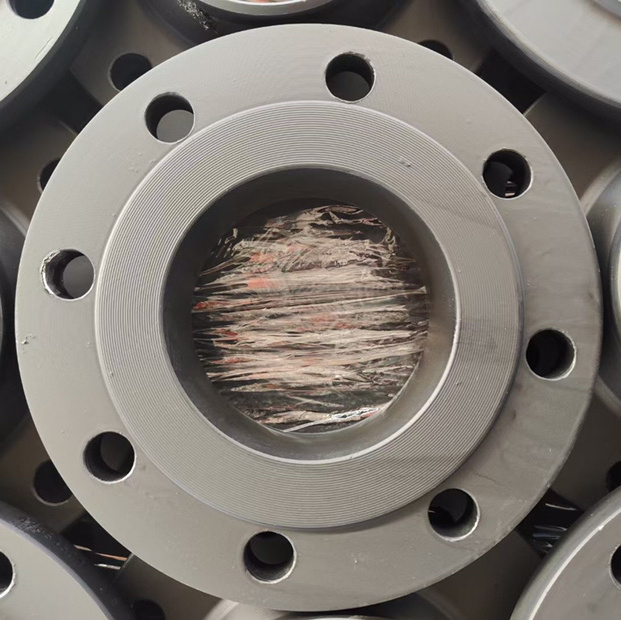

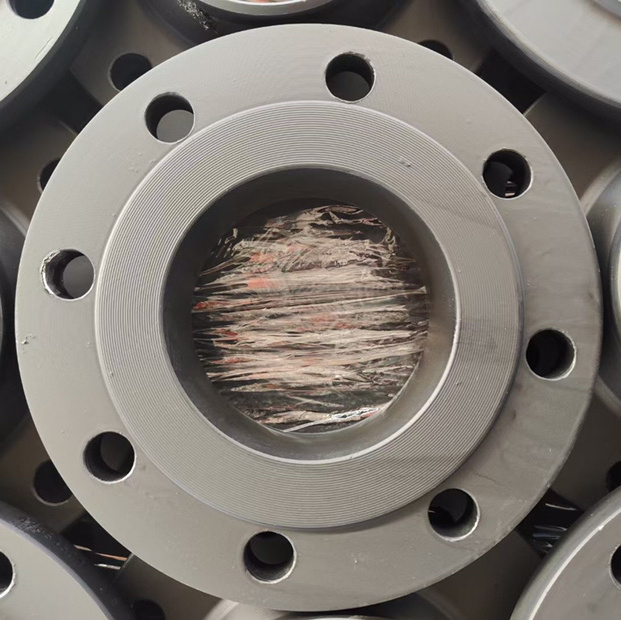

About Flange

A flange is an important component used to connect pipes, valves, equipment, or other piping components. It usually exists in a circular flat or circular shape, with screw holes for connecting to other components. Classification 1. Welding Neck Flange 2. Slip on Hubbed Flange 3. Plate Flange 4. ...Read more -

What information can we learn about rubber expansion joints

Rubber Expansion Joint is an elastic connection device used in pipeline systems, mainly used to absorb and compensate for pipeline deformation caused by temperature changes, vibration, or pipeline movement. Compared with metal expansion joints, rubber expansion joints usually use rubber or synthe...Read more -

Analyze the similarities and differences between welded elbows and forged elbows.

Forged elbow is a pipe fitting that changes the direction of the pipeline. As it is forged, it can withstand higher pressures up to 9000LB, so some people also call it a high-pressure elbow. Welding elbows can be cut and welded onto pipelines or steel plates, with a wide range of specifications. ...Read more -

What are the impacts of different thicknesses flanges?

1.Capacity: Thicker flanges are usually better able to withstand pressure and torque. In high-pressure or high torque applications, choosing thicker flanges can provide stronger support. 2.Cost: Generally speaking, thicker flanges require more materials, so they may be more expensive. In the cas...Read more -

What are the differences and advantages and disadvantages of disassembling the power transmission joint compared to metal compensators

Dismantling transmission joints and metal compensators are two different mechanical components that have significant differences in design, function, and application. The following are their differences and their respective advantages and disadvantages: Dismantling joint: Differences: 1. Usage: D...Read more -

About EN1092-1 standard

EN 1092-1 is a European standard that specifies flanges and flange connections. Specifically, it specifies the requirements for the size, design, materials, and testing of flange connections. This standard is mainly used for the connection between pipeline systems and equipment, ensuring the reli...Read more -

Japanese standard SS400 and national standard Q235 what is the difference?

SS400 is a marking method of Japanese steel materials and a judgment standard. Structural steels in foreign standards are often classified according to tensile strength, such as SS400 (marked as such in Japan), where 400 represents σ The minimum value of b is 400MP. Ultra high strength steel ref...Read more -

We have obtained an ISO certification certificate.

Just yesterday, our company received the ISO 9001 qualification certification, which is a very happy event for us. In recent years, customers have increasingly focused on the quality inspection results of products, rather than simply using price as the sole criterion for measurement. Our company ...Read more -

Difference between SUS304 stainless steel and SS304.

SUS304 (SUS means stainless steel for steel) stainless steel austenite is usually called SS304 or AISI 304 in Japanese. The main difference between the two materials is not any physical properties or characteristics, but the way they are quoted in the United States and Japan. However, there are m...Read more -

About Metal bellows

Metal bellows is a metal pipe with a corrugated structure, usually made of metal materials such as stainless steel. Its main features are flexibility, bendability, corrosion resistance and high temperature resistance. Types of corrugated pipes: According to different corrugated structures, metal...Read more -

About Rubber Expansion Joint.

What is a rubber expansion joint? Do you know? The various similar names of expansion joint products make people dizzy when choosing. In order to better distinguish these expansion joints, today I will introduce one of them – rubber expansion joints, to help you have a clearer understanding...Read more -

How to prevent rust on stainless steel pipes?

Although stainless steel has strong corrosion resistance, corrosion may still occur in certain special environments or specific usage conditions. Therefore, it is important to carry out appropriate rust prevention treatment on stainless steel pipes. The following are some common rust prevention m...Read more -

How to distinguish between welding neck flange and lap joint flange

Welding neck flange and lap joint flange are two common flange connection methods, which have some obvious differences in structure and can be distinguished by appearance and connection method. Neck structure: Butt welding flange with neck: This type of flange usually has a protruding neck, and ...Read more -

Do you know about butt welding and butt welding connections?

Butt welding is a common welding method that involves heating the ends or edges of two workpieces (usually metals) to a molten state and then joining them together through pressure. Compared to other welding methods, butt welding typically uses pressure to form the connection, while heat is used ...Read more -

Differences and Similarities between ASTM A153 and ASTM A123: Hot Dip Galvanizing Standards

In the metal product industry, hot-dip galvanizing is a common anti-corrosion process. ASTM A153 and ASTM A123 are two main standards that regulate the requirements and procedures for hot-dip galvanizing. This article will introduce the similarities and differences between these two standards to ...Read more -

ASTM A153: Standard for hot-dip galvanized metal parts

Hot dip galvanizing is a widely used protection technology for metal products, which forms a zinc coating on the metal surface to prevent corrosion. During this process, the ASTM A153 standard became an important guide in the field of hot-dip galvanizing. This article will provide a detailed intr...Read more