Sekhahla se hubbed holim'a flangeke mofuta oa flange, o sebelisoang haholo indastering ea mechini mme o rorisitsoe ke basebelisi.Sengoliloeng sena se tla u fa kenyelletso e qaqileng ea melemo e meng ea ho thella ha molala ho li-welding flange lits'ebetsong tsa indasteri bakeng sa khetho ea hau le litšupiso:

1. Joalo ka ha hubbed slip ka flange na le e nyenyane e khutšoanyane molala ho fetaplate flange bakeng sa ho tjheseletsa,eo ka tloaelo e tsejoang e le plate flange, ho satalla ha flange ho ntlafatsoa haholo, kahoo e ka sebelisoa ho liphaephe tse nang le tekanyo e phahameng ea khatello.

2. Molala o bataletseng oa ho tjheseletsa flange o ka sebelisoa ka mefuta e mengata ea libaka tsa ho tiisa ho feta platelet flat welding flange.Liphaepheng tse nang le likhatello tse phahameng, sefahleho sa concave le convex kapa sefahleho sa mortise se ka sebelisoa bakeng sa ho tiisa.

3. Molala o bataletseng oa ho cheselletsa flange hangata o sebelisoa khatellong e tlase kapa liphaepheng tsa khatello e mahareng, e leng mofuta o betere oa welding.Sena se bakoa ke hore liphaephe le flange li batla li otlolohile 'me ho bonolo ho li kenya, 'me phaephe ha e sekame habonolo.

4. Molala o bataletseng oa welding flange ha o boloke sebaka le boima ba 'mele feela, empa hape o tiisa hore lenonyeletso le ke ke la tsoa le ho ba le ts'ebetso e ntle ea ho tiisa.Lebaka leo ka lona boholo ba flange bo fokolitsoeng ke hore bophara ba tiiso bo fokotsehile, e leng ho tla fokotsa karolo ea sebaka sa ho tiisa.

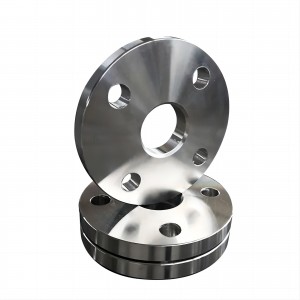

(Hubbed Slip On Flange) (Plate flange bakeng sa welding)

Tšebeliso ea "neck slip" holim'a welding flange e batla e pharaletse, 'me boholo ba ts'ebeliso bo khethoa ho latela litšobotsi tse fapaneng.Bongata ba tsona li sebelisoa ha maemo a mahareng a batla a le bonolo, joalo ka khatello e tlase e sa hloekisoang moea o hatelitsoeng le khatello e tlase e potolohang ea metsi.Molemo oa eona ke hore theko e batla e le theko e tlaase.

Necked flat welding flange e sebetsa ho mefuta e meng ea khatello, eo hangata e sebelisetsoang ho hokahanya liphaephe tsa tšepe tsa 0.6 — 4.0MPa.Bokaholimo ba tiiso ea molala o bataletseng oa welding flange e ka etsoa ka mefuta e meraro: mofuta o boreleli, mofuta oa concave convex le mofuta oa tenon groove.Molala o boreleli oa ho cheselletsa flange o sebelisoa haholo, 'me mefuta e meng e' meli ea molala o bataletseng oa welding flange le eona e tloaelehile ho sebelisoa.Li-flange tse nang le molala li kenyelletsa mefuta e mengata le mehlala.Ha ho bapisoa, tjheseletsa molala flangesli sebelisetsoa ho cheselletsa butt ea li-flange le liphaephe.Li sebelisoa haholo ho theknoloji ea welding, e nang le litšobotsi tse ntle tsa ts'ebeliso le ts'ebetso.Li na le sebopeho se utloahalang, matla a maholo le ho satalla, li khona ho mamella mocheso o phahameng le khatello e phahameng, ho khumama khafetsa le ho fetoha ha mocheso, 'me li na le ts'ebetso e tšepahalang ea ho tiisa.Khatello ea bona e tloaelehileng hangata ke 1-25MPa.

Ho phaella moo, tjheseletsa pakeng tsa molala butt tjheseletsa flange le nozzle ke ea Class B tjheseletsa, ha tjheseletsa pakeng tsa molala bataletseng tjheseletsa flange le nozzle ke ea Class C tjheseletsa.Teko e sa senyeheng ka mor'a welding e fapane pakeng tsa bona.

Nako ea poso: Dec-08-2022