Hubbed slip on flange is a kind of flange, which is widely used in the mechanical industry and has been praised by users. This article will give you a detailed introduction to some advantages of the neck slip on welding flange in industrial applications for your selection and reference:

1. As the hubbed slip on flange has a small short neck more than the plate flange for welding, which is commonly known as the plate flange, the stiffness of the flange is greatly improved, so it can be applied to pipes with higher pressure rating.

2. The neck flat welding flange can be used with more types of sealing surfaces than the plate flat welding flange. In the pipeline with higher pressure rating, the concave and convex face or mortise face can be used for sealing.

3. The neck flat welding flange is generally used in low pressure or medium pressure pipelines, which is a better type of welding. This is because the pipeline and flange are relatively vertical and easy to insert, and the pipeline is not easy to tilt.

4. The neck flat welding flange not only saves space and weight, but also ensures that the joint will not leak and has good sealing performance. The reason why the flange size is reduced is that the diameter of the seal is reduced, which will reduce the section of the sealing surface.

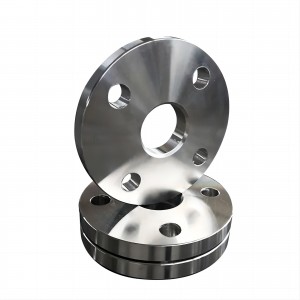

(Hubbed Slip On Flange) (Plate flange for welding)

The use of neck slip on welding flange is relatively wide, and the scope of use is determined according to different characteristics. Most of them are used when the medium conditions are relatively mild, such as low pressure non purified compressed air and low pressure circulating water. Its advantage is that the price is relatively cheap.

Necked flat welding flange is applicable to the nominal pressure range, which is generally used for the connection of 0.6 — 4.0MPa steel pipes. The sealing surface of the neck flat welding flange can be made into three types: smooth type, concave convex type and tenon groove type. The smooth neck flat welding flange is widely used, and the other two types of neck flat welding flange are also common in use. Necked flanges include many types and models. In comparison, welding neck flanges are used for butt welding of flanges and pipes. They are mainly used in welding technology, with good use characteristics and performance. They have reasonable structure, large strength and stiffness, can withstand high temperature and high pressure, repeated bending and temperature fluctuations, and have reliable sealing performance. Their nominal pressure range is generally 1-25MPa.

In addition, the weld between the neck butt welding flange and the nozzle belongs to Class B weld, while the weld between the neck flat welding flange and the nozzle belongs to Class C weld. The non-destructive testing after welding is different between them.

Post time: Dec-08-2022