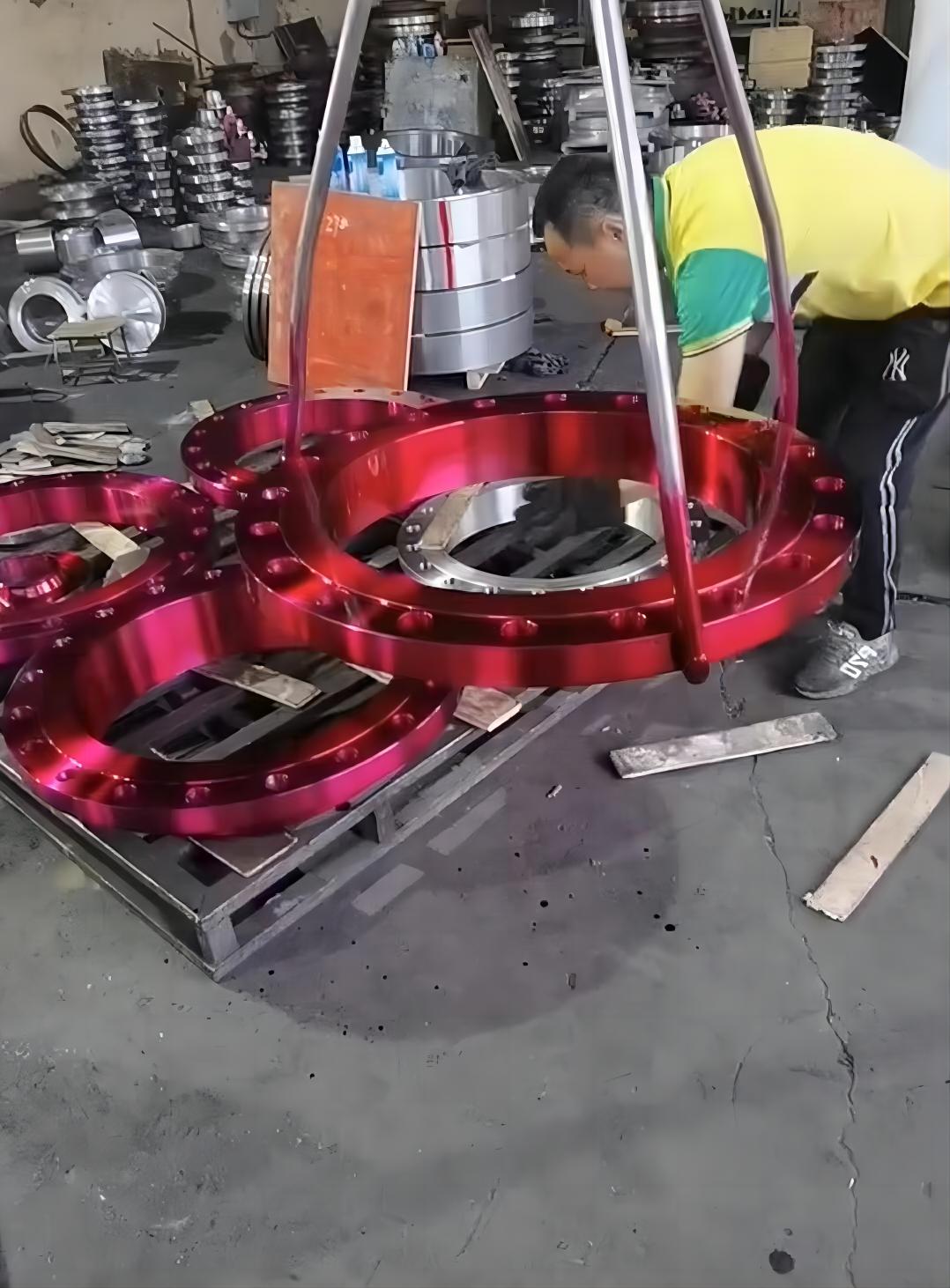

A flange refers to opening several fixing holes around a metal body similar to a disc, which are then used to connect other things; In fact, in assembly and processing, many enterprises will use parts such as flanges. If there is a significant deviation in the center of the flange connection hole, it may cause the flange to be unable to connect with other accessories normally. Therefore, in order to better use the flange and maximize its sealing performance, we must inspect the flange.

So, what tools are used to detect flanges? What is the flange detection method?

1、 Preparation work before flange measurement

1. It is best to arrange for three people to take measurements before measurement, with two people taking measurements and one person proofreading and filling out the form.

2. The measuring tools that need to be prepared include calipers, measuring tapes, vernier calipers, etc.

3. Before measuring, based on the flange position, first draw a sketch of each connecting pipe flange of the equipment and number it consecutively, so that the fixture can be installed with corresponding numbers.

Measurement range

Measure various dimensions such as flange inner diameter, outer diameter, hole spacing, and hole diameter.

With the continuous development of economy and technology, a new type of flange detection tool has emerged, which uses a portable joint arm to detect the accuracy of the flange, which is both precise and efficient.

In order to ensure the tightness of the connections between various parts, precision dimensional testing is required for flanges during processing and production to ensure that there are no quality issues with the product.

Solution

The usage method of portable coordinate measuring instruments, which can be started with one click, can solve the problems of low accuracy and poor consistency in traditional manual detection, quickly measure results, and complete flange size measurement with high efficiency and precision.

It is easy to see that after the various accuracy tests of the flange are qualified, another part of the flange will be connected to it and fixed with bolts. Therefore, whether in terms of aperture or pitch, there are still certain requirements for accuracy. It is also necessary to use a portable joint arm for flange accuracy testing.

Precautions

1. Because during installation, the flanges may have different outer diameters, misalignment, and uneven gasket thickness, the processed fixture should correspond to the flange on its side and cannot be interchanged. Therefore, measuring the dimensions and numbers of each part is the key to fixture processing and installation.

2. Fill in the table with the measured data. Measurement is a meticulous task, and measurement and recording must be prepared without errors. When filling out forms, it is important to be careful and clear.

Post time: Apr-23-2023