Reducer is one of the chemical pipe fittings, which is used to connect two different pipe diameters. It can also be divided into concentric reducer and eccentric reducer.

Reducer material: including stainless steel reducer reducer, alloy steel reducer reducer and carbon steel reducer.

Production method

The roundness of the reducer shall not be greater than 1% of the outer diameter of the corresponding end, and the allowable deviation shall be ± 3mm. The materials of reducers shall comply with SY/T5037, GB/T9711, GB/T8163, American standard ASTM A106/A53 GRB, API 5L, APT5CT, ASTM A105, ASTM A234, ASTM A106, DIN German standards and customer requirements

Reducer is a kind of pipe fitting used at pipe reducer. The commonly used forming process is reducing, expanding or reducing plus expanding, and stamping can also be used for reducing pipes of certain specifications.

1. Reducing forming/expanding forming

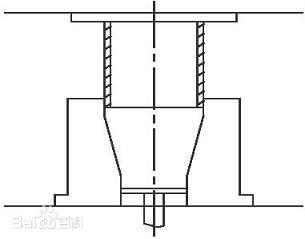

The reducing forming process of reducing tube is to put the tube blank with the same diameter as the large end of reducing tube into the forming die, and make the metal move along the die cavity and shrink to form by pressing along the axial direction of the tube blank. According to the size of reducer, it can be divided into one press forming or multiple press forming.

Expanding forming is to use the tube blank with the diameter smaller than the big end diameter of the reducer, and use the internal die to expand along the inner diameter of the tube blank. The expanding process is mainly used to solve the problem that the reducer with large diameter change is not easy to be formed by reducing. Sometimes, according to the requirements of material and product forming, the expanding and reducing methods are combined.

In the process of reducing or expanding deformation and pressing, cold pressing or hot pressing shall be adopted according to different materials and reducing conditions. In general, cold pressing shall be adopted as far as possible, but hot pressing shall be adopted for severe work hardening caused by multiple reducing, wall thickness being too thick or alloy steel materials.

(Schematic diagram of reducing forming)

2. Stamping

In addition to using steel pipes as raw materials to produce reducers, steel plates can also be used to produce reducers of some specifications by stamping process. The shape of the die used for drawing is designed according to the size of the inner surface of the reducer, and the steel plate after blanking is pressed and drawn by the die.

Application

1. When the flow of fluid in the pipeline changes, such as increasing or decreasing, and the flow rate requires little change, reducer shall be used.

2. In order to prevent cavitation at the pump inlet, a reducer is required.

3. At the joints with instruments, such as flow meters and regulating valves, reducing pipes are also required to match with the joints of instruments.

Classification

Divided by material:

Carbon steel: ASTM/ASME A234 WPB, WPC

Stainless steel: ASTM/ASME A403 WP 304-304L-304H-304LN-304N

ASTM/ASME A403 WP 316-316L-316H-316LN-316N-316Ti

ASTM/ASME A403 WP 321-321H ASTM/ASME A403 WP 347-347H

Divided by production method:

It can be divided into pushing, pressing, forging, casting, etc.

Divided by manufacturing standards:

It can be divided into national standards, electrical standards, ship standards, chemical standards, water standards, American standards, German standards, Japanese standards, Russian standards, etc.

Post time: Jan-03-2023